Armature varnish manufacturer

Armature varnish is a necessary commodity used in manufacturing and repairing DC generators and motors. An armature is the rotating member of this type of equipment, and it is a core along with windings that are subjected to severe mechanical, thermal, and electrical stresses.

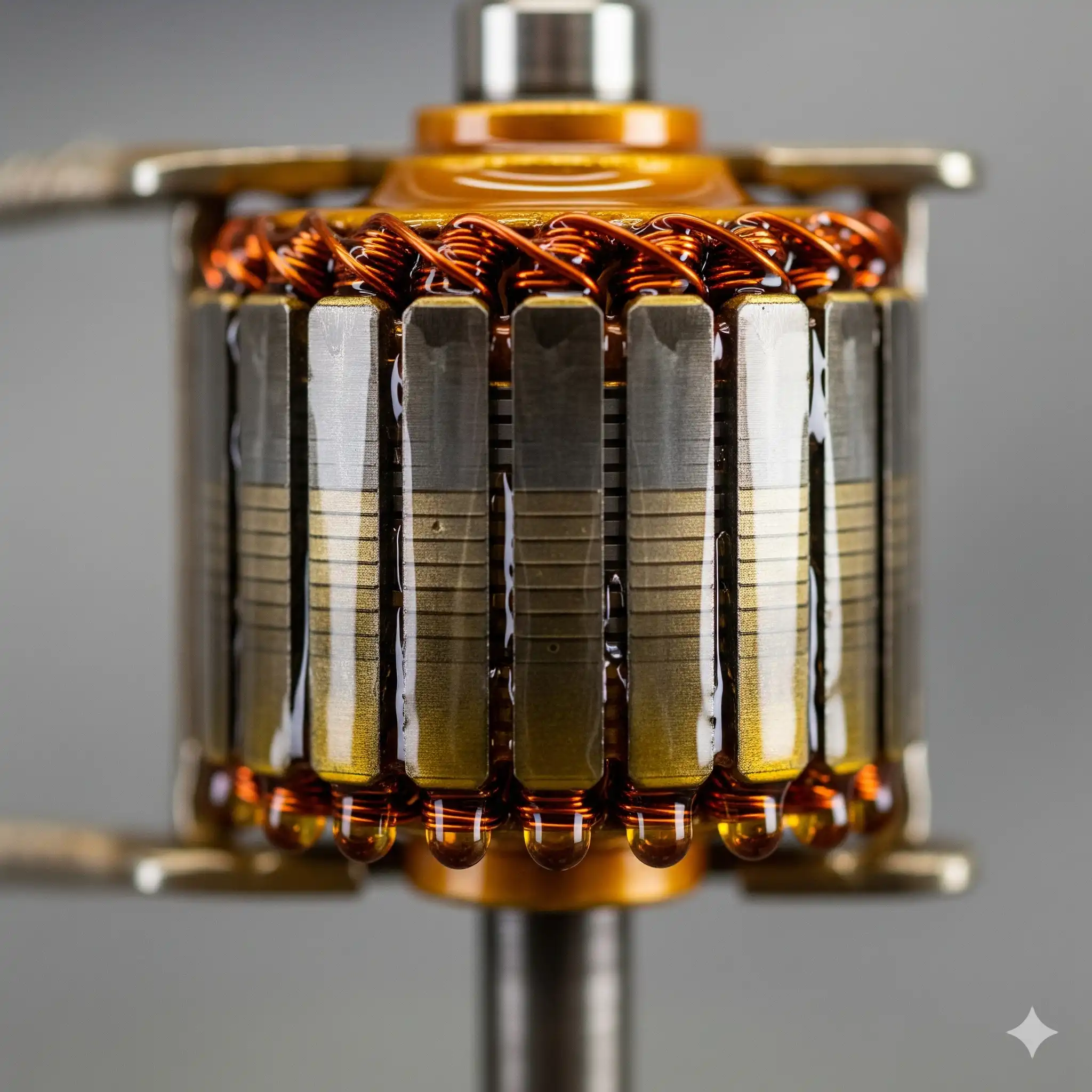

Varnish is impressed on armature windings through an impregnation process in order to provide them with the necessary structure and performance. The primary function of this varnish is to create a high-strength layer of electrical insulation. Rapid rotation and reversing magnetic flux inside a motor or generator puts incredible electrical stress on the windings. Varnish fills the air gaps between the wires and provides a high-dielectric-strength shield against short circuits and flashovers, the usual causes of armature failure.

In addition, varnish provides significant mechanical support. The centrifugal forces brought about by the rotating armature are colossal, and such forces, compounded by the vibrations introduced by the magnetic fields, might lead to loosening, displacement, or even fracture of the windings.

The hardened varnish is a solid, hard mass that encloses the windings tightly and holds them in place from such movement, thereby making the armature steady and balanced. This mechanical support also assists in the effective dissipation of heat since the varnish enhances thermal conductivity from windings to armature core to avoid localized hotspots that cause damage to the insulation. The varnish also protects the armature from outside contaminants (such as moisture, oil, and dirt), which leads to insulation failure, and corrosion of metal components. For this reason, armature varnish is a highly specialized product to endure the harsh conditions present in an operating rotating electric machine; providing the protection necessary to operate efficiently and reliably through an extended period.