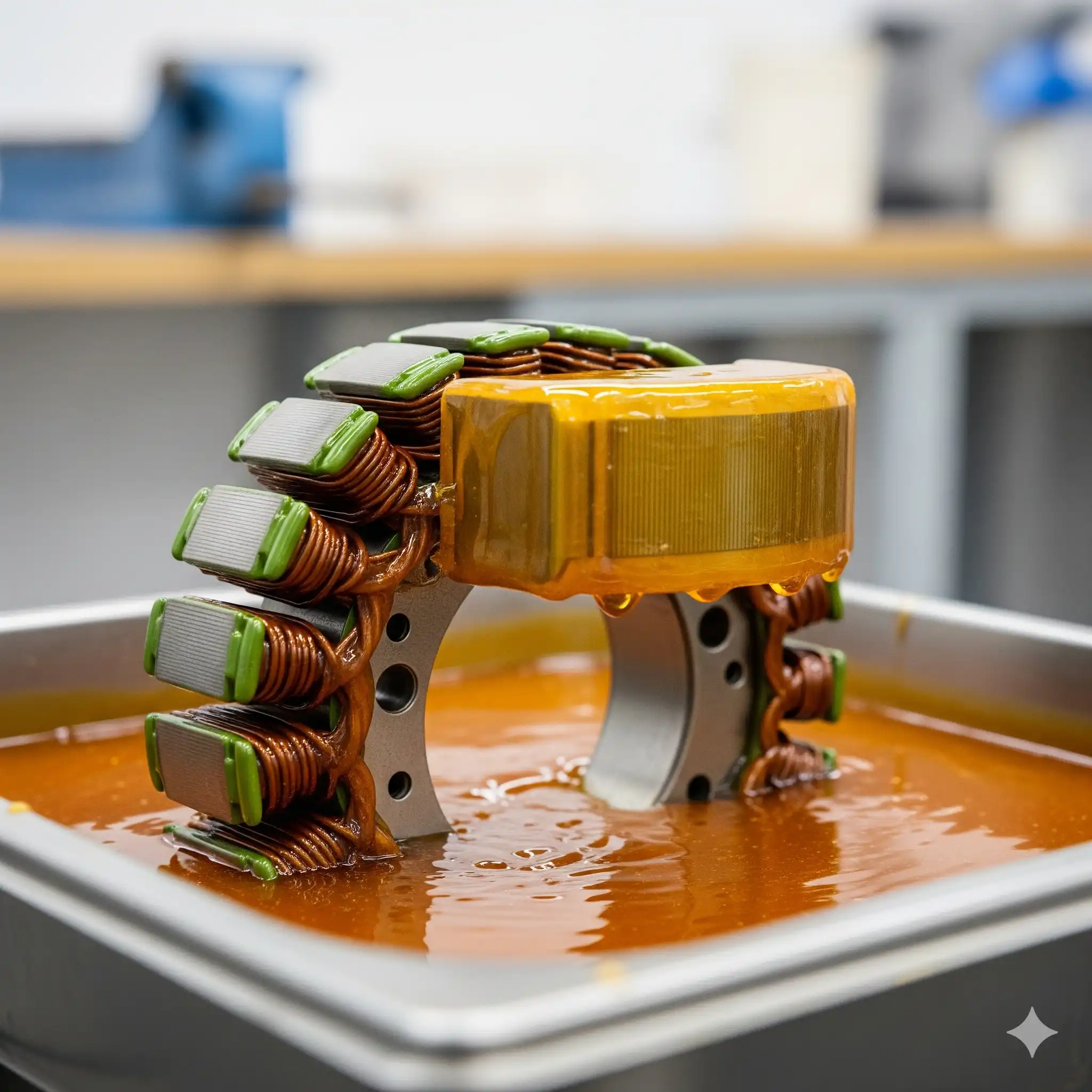

Air Drying Varnish in electric motors

Varnish is more than a mere cosmetic coating on electric motors; it is part of their electrical and mechanical integrity. The windings and coils in an electric motor are subject to continuous heat, electrical stress, and mechanical stress. Varnish is used to provide these products with a hard protective coating that is responsible for the long-term reliability of the motor.

Its main purpose is as top-level electrical insulation. By the varnishing process of windings, varnish seals small air pockets and wire holes between wires that are vulnerability points for electric insulation.

It prevents arcing and short circuiting leading to catastrophic failure of the motor. The varnish deposits a strong, uniform dielectric film that isolates each wire properly so that the motor may safely and efficiently operate on a variety of voltages.

Apart from electrical insulation, varnish plays an essential role in motor mechanical robustness. The strong electromagnetic forces present in a motor's operation can lead to windings vibration. With no binding agent, these vibrations will result in a situation known as "turn-to-turn shorts," whereby the insulation in between two conductors wears out and shorts the circuit. Varnish, after hardening, creates a hard, stiff plug retaining the windings in place and restraining them from causing this self-destructive movement. The mechanical support also causes heat dissipation to be more efficient, as the stiff varnish enhances thermal conductance from the windings to the motor core to cool the motor. Varnish also offers a firm shield against external dangers. Appropriate varnish, its resistance to chemicals and heat stability being an essential aspect of contemporary motor design, yields maximum performance, long service life, and minimum maintenance cost.